Made for biomass

Denso Made

Universal

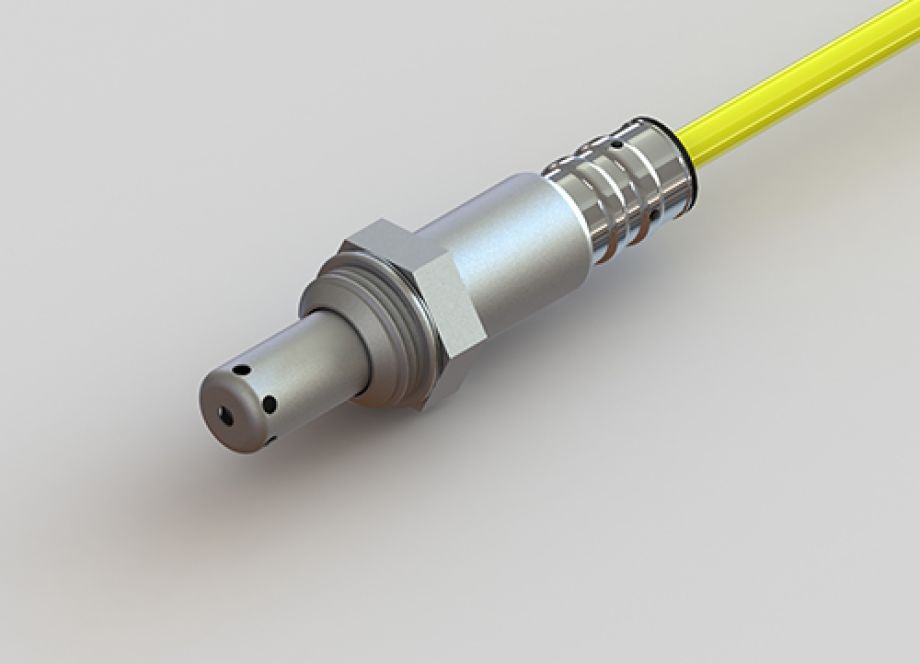

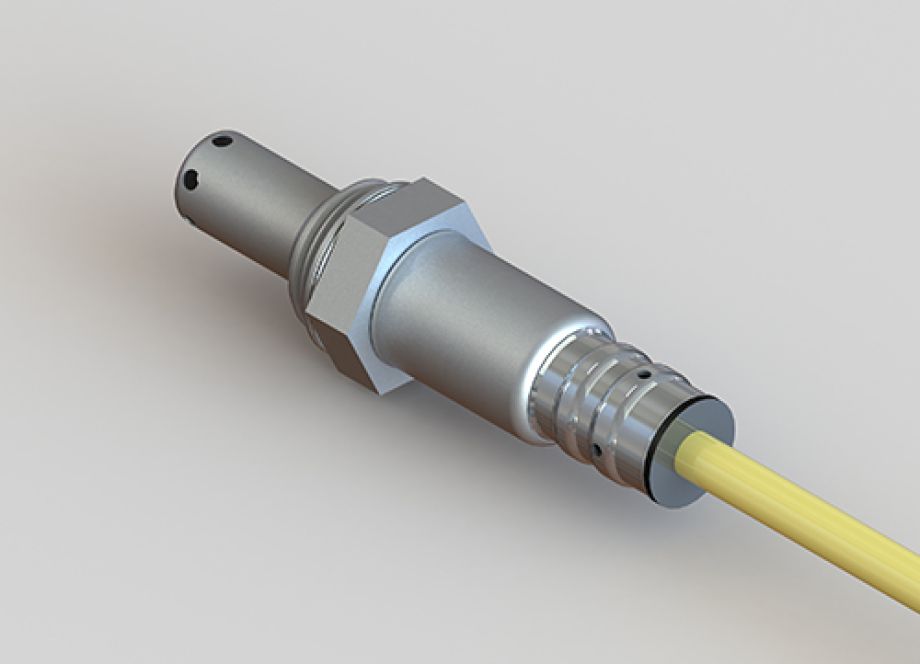

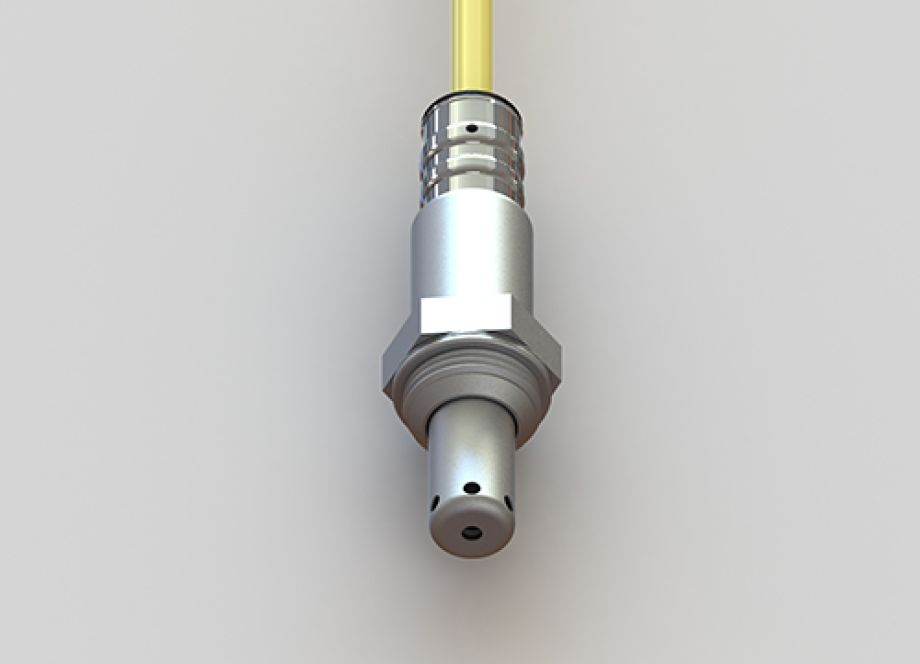

Biomass burner and boiler oxygen sensor

Introducing the OSx Oxygen Sensor made for biomass burner, an advance technology to maximises burner performance and solid fuel efficiency while reducing harmful emissions.

The OSx oxygen sensor have been designed by DENSO Corporation in cooperation with FKK Corporation to measure the pro- portion of unburned oxygen in exhaust gases of biomass, especially wood pellet burner systems.

This oxygen sensor with integrated zirconium heater, provide an output signal in the range of lambda and make it capable of being used as universal lambda sensor in every biomass burning appliances.

Applications

- Pellet boiler

- Wood chips boiler

- Biomass boiler

- Other biomass burner

- Commercial burner

- Industrial burner equipment

- Other laboratory equipments

What role do lambda sensors play?

In order to reduce emissions, modern biomass boiler have been designed to carefully control the amount of solid fuel they burn.

The Lambda (or Oxygen) Sensor is a critical component in this process, its goal is to work together with the boiler’s auger, inlet and exhaust air fan and electronic control unit (ECU) to achieve the lowest possible output of environmentally harmful exhaust gas emissions and biomass fuel consumption whatever the fuel quality.

The Lambda Sensor does this by monitoring the percentage of unburned oxygen present in the burner’s exhaust gases. This data is fed to the boiler’s ECU, which adjusts the A/F (air/solid fuel) mixture. The correct air/solid fuel mixture enables the burner to run efficiently, reducing solid fuel consumption and CO2, NOX, HC emissions.

Denso O2 sensor technology benefits

-

Save energyCan cut fuel (e.g. pellet) annual consumption and emission by 20%

-

RangeDetects a broad range of air-fuel ratio up to 21%

-

OptimizeAllow an easy adapatation of burner output whatever fuel quality (pellet)

-

Life spanLong lasting (non-aging) due to Denso quality

-

VersatileBuilt-in heater to run at all exhaust gases temperatures

-

InstallationEasy to install, service and retrofit

-

RobustnessExcellent water resistance and air tightness

-

CertificationComply with RoHS, REACH regulation on Hazardous Substance

-

QualityMade in Japan by Toyota car No.1 supplier. 100% checked before shipment