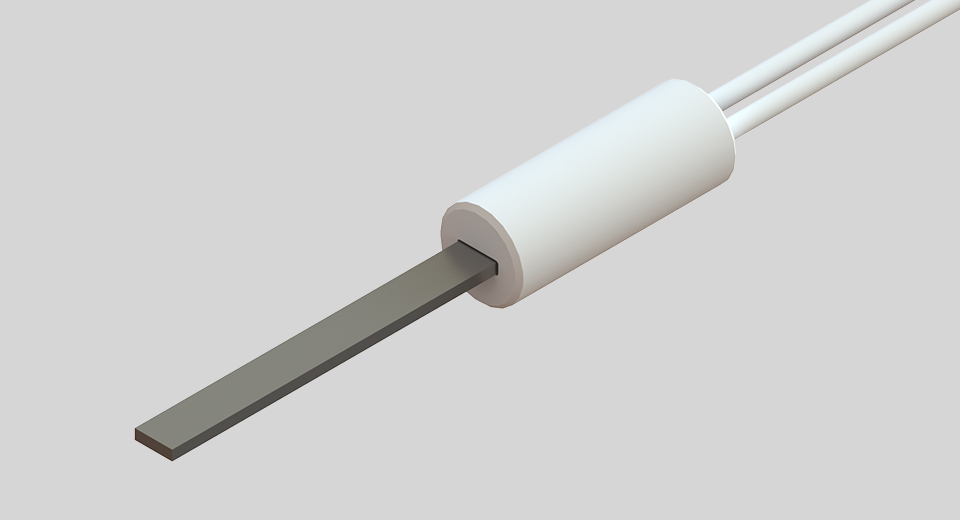

Silicon nitride hot surface igniter as flame temperature sensor (2)

In the previous post, we have seen that it is possible to use a silicon nitride hot surface igniter as a temperature sensor in certain conditions, in this post we want to explain the application of this principle.

Silicon nitride hot surface igniter (HSI) are usually used to ignite a gas air mixture in a water boiler/furnace or burner, however it is possible to use them to control the gas air ratio in a close environment. Silicon nitride hot surface igniter have a temperature dependent electrical resistance (PTC), so measuring the resistance of a not powered heating element mounted into the burner flames could allow to measure the temperature. Knowing flame temperature allow to accurately calculte the optimum combustion point inside a burner (Air–fuel equivalence ratio, λ (lambda) or stoichiometric ratio) thus achieve a better fuel efficiency and less emmission.

At a given scope of airmassflow (or fan speed) in a close loop burner, where mass flow is controled from inlet air to exhaust, the silicon igniter resistance inside the flame can be correlated to a stoichiometric ratio. If the correlation is well calibrated, then adjusting the flame temperature depending on igniter resistance reading and airmassflow allows to set the desired optimum cobustion point (lambda).

Advantages:

- Dual use of the igniter: as igniter and flame tempeture sensor = cost reduction

- Knowing flame temperature allow to accurately calculte the optimum combustion point = better fuel efficiency, less emmission

- Not need of flame monitoring as the temperature can indicate if there is flame or not

- SN igniter are very robust to chemical and high temperature

- Allow flame monitoring in place where ionization method is not possible (ex: hydrogen mixture burning)

FKK Corporation will continue R&D especially in the purpose to use these property in Green Hydrogen (H2) combustion burner.