How work ceramic igniter in biomass/pellet applications

Here you will find an overview of how HTH ceramic igniter works in wood pellet stoves, wood pellet boilers and woods chips boilers.

HTH ceramic igniters are printed film PTC resistance encapsulated in ceramic alumina to deliver the best efficieny and resist to corrosion. In biomass heating applications, ceramic igniter are use in combination with primary air ventilator or exhaust fan to heat air passing around or throught the heating element. When air blowed in the burner or in the grate reach 200 to 300°C, biomass combustible immediatly ignite.

Compare to convetional cartridge heaters or heat gun, ceramic igniters only use a fraction of power and ignition speed is reduced by 2~3 minutes. Beside as HTH ceramic igniters are impervious to corrosion, they last for long years.

Below you will find several diagrams showing how ceramic igniters work in different types of biommas burners.

Pot burner

Pot burner are the most common configuration in pellet stove applications. An auger feed load pellet into the grate by gravity.

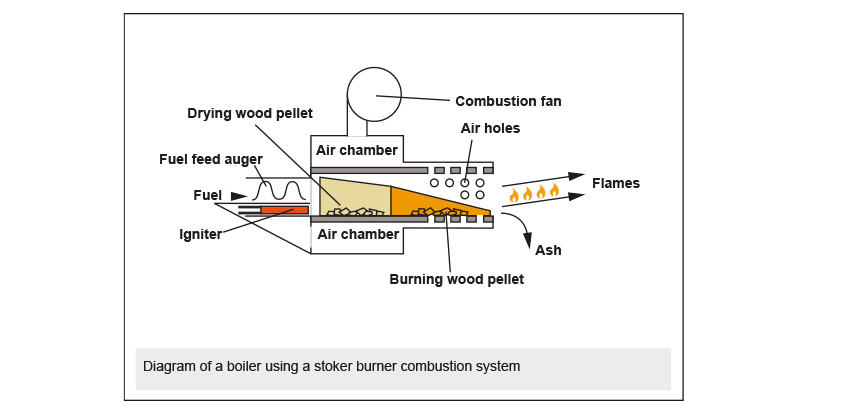

Stoker burner

Stoker burner boilers are the simplest boilers, having a relatively small grate attached directly to the end of the feed auger. Stoker burner boilers can burn wood pellets and wood chips up to 30% moisture content. These boilers usually have moderate levels of refractory lining and are not of the high water content (HWC)type in order to produce a fast response to heating load demands. On small stoker burner boilers there may be only one combustion fan as shown in the diagram, which means that it is very difficult to separate the primary air supply to the grate from that in the final combustion zone above the grate. As a result the potential for overheating and subsequent slag formation on the grate is very high, and some burner manufacturers have included rotating grate system as a preventative measure.

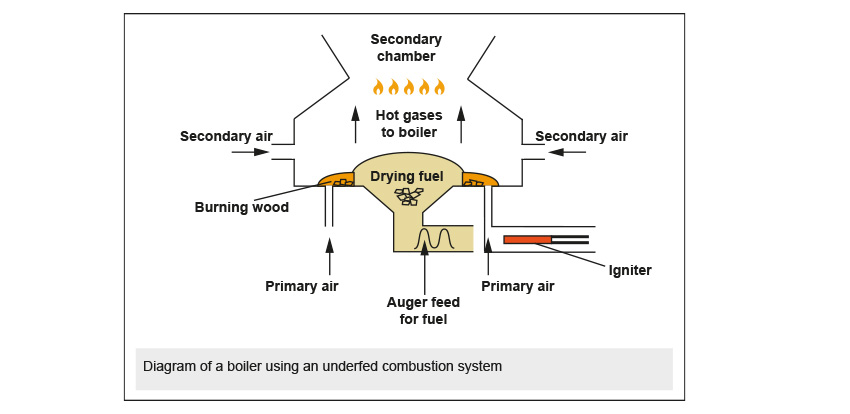

Underfed burner

In an underfed combustion system the fuel is pushed up through an inverted cone to form a dome of fuel on which combustion takes place (see diagram). The auger enters beneath the combustion chamber and, because combustion occurs upwards, may not need to be emptied at boiler shut down. Underfed stoker boilers can burn wood pellets and wood chips up to 30% MC. Some may be designed specifically for use only with pellets, in which case very little refractory lining may be installed. For wood chips up to 30% MC a moderate level of refractory lining will be installed, and the boiler is usually limited in the size of wood chip it can accept. Again, they are designed for a reasonably fast response to heating load demands.

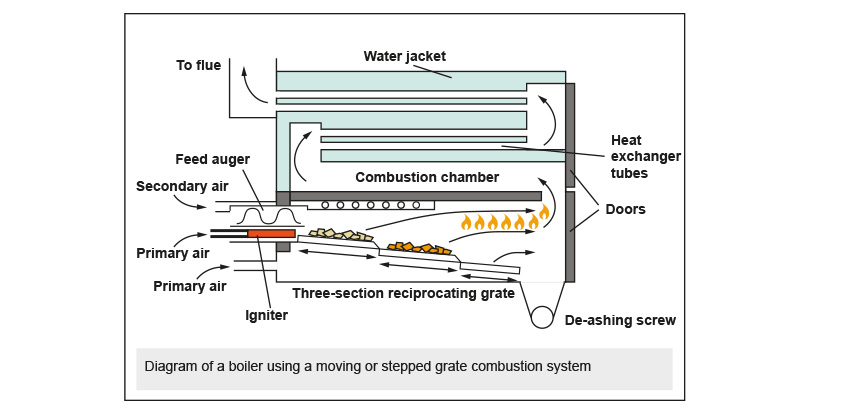

Moving grate or stepped grate burner

Moving grate boilers, also known as stepped grate or inclined grate boilers, allow the greatest flexibility in boiler design but usually have the slowest response because of the much greater levels of refractory lining installed to enable them to be used with wood chip of up to 50% MC.Moving grate boilers are designed to burn wood chip with a MC of between 30% and 50%. The boiler can be either auger or ram stoker fed. Moving grate boilers are also suitable for burning dry wood chip and some will also burn pellets.