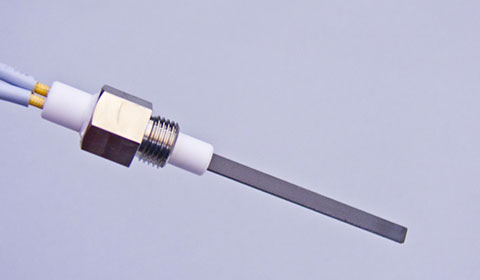

Hot surface igniter for fuel cell reformer/combustor

Since 2011, FKK is producing a variety of silicon nitride ceramic igniter models for hydrogen / fuel cell appliances in Japan, Korea and the rest of the world.

We originaly started to supply fuel cell appliance manufacturers of the Japanese New Energy and Industrial Technology Development Organization (NEDO) fuel cell program.

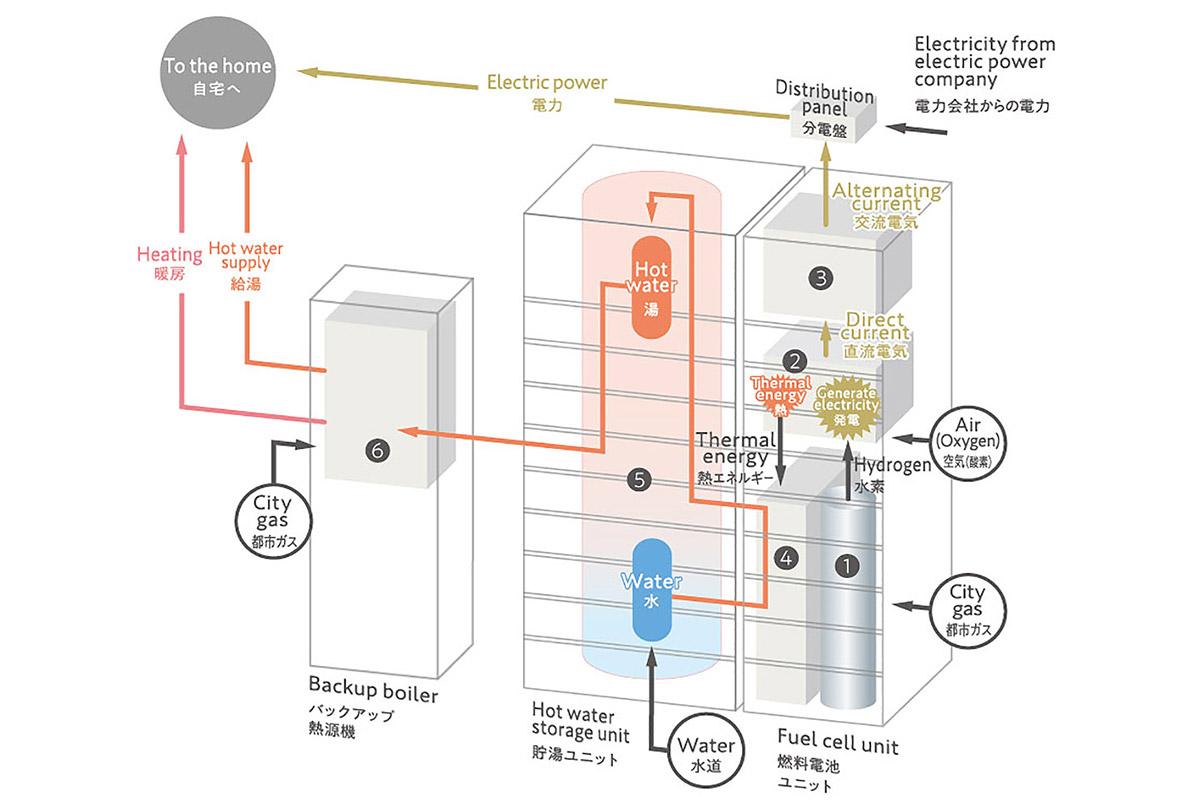

The goal of the program was to develop fuel cell cogeneration (CHP) appliances that can generate heat and electricity from natural gas to increase Japanese resiliency and lower Japan CO2 footprint.

Many famous japanese appliances manufacturers work on it and quickly came with original solution (Ene farm), allowing to produce 50~70 of household electricty with same natural gas consumption as a normal gas boiler.

FKK hot surface igniter in fuel cell / hydrogen systems

Inside these systems, FKK's ceramic hot surface igniter are used in fuel cell reformer unit (① on diagram above), water heater ignition, pre-heat/start-up burner (④ on diagram above), desulfurization unit, back-up boiler (⑥ on diagram above), off-gas burner, etc so they play an essential role in the system.

Most of these system (SOFC or PEFC) transform natural gas (methan) into hydrogen that is then feed to fuel cell stack that will generate electricity. Waste heat from the stack and fuel reformer is used to heat water for the home.

Using methan gas to produce hydrogen, is not the best solution for environment, but could play a role of transition to 100% green hydrogen in the future.In the future it would also be possible to run household water boiler with pure hydrogen. In these next generation systems too, FKK ceramic igniter can play an essential role.

How to reform city gas into hydrogen

Hydrogen can be transformed from natural gas into hydrogen by 2 methods:

- Steam-methane reforming reaction: CH4 + H2O (+ heat) → CO + 3H2

- Partial oxidation of methane reaction: CH4 + ½O2 → CO + 2H2 (+ heat)

Then a Water-gas shift reaction is needed: CO + H2O → CO2 + H2 (+ small amount of heat)

Ceramic igniter, busbar and electrode line-up

High reliability and quality

Rating lige of over 90000 hours (nearly 10 years) of continuous powering even in fuel cell high temperature and oxidizing environment.

Very high temperature

1350°C steady state temperature in 30s, 1000°C in less than 6s.

Wide variety of design

Many design available: round, square flange, thread flange, buit-in thermocouple, etc.

Fuel cell reformer busbar

FKK also producing high temperature resistant ceramic parts and busbars and spark electrode for fuel cell systems.