How does a pellet stove igniter work?

Here you will find all you want to know about pellet stove igniter:

Basic working

A pellet stove ceramic ignitor works the same way as an electric stove's heating element, or a hair dryer heating element.

Most of modern pellet stove are now fully automatic, pushing the start button of the stove will start the ignition process of wood pellet combustible.

The extremely high heat from the ceramic ignitor surface will heat the air and will then ignite the extremely flammable wood pellets. Usualy air blowed in the burner or in the grate nead to reach 200 to 300°C to make wood pellet spontaneously ignite.

Thanks to ceramic igniter, most of modern pellet stove are now achieving an ignition time between 50s and 120s (first sustainable flame).

Structure

Aluminium oxyde (alumina) ceramic heating element are developed based on ceramic lamination technologies: internal heating elements are protected from oxidation in air due to a sintered one-piece ceramic body construction.

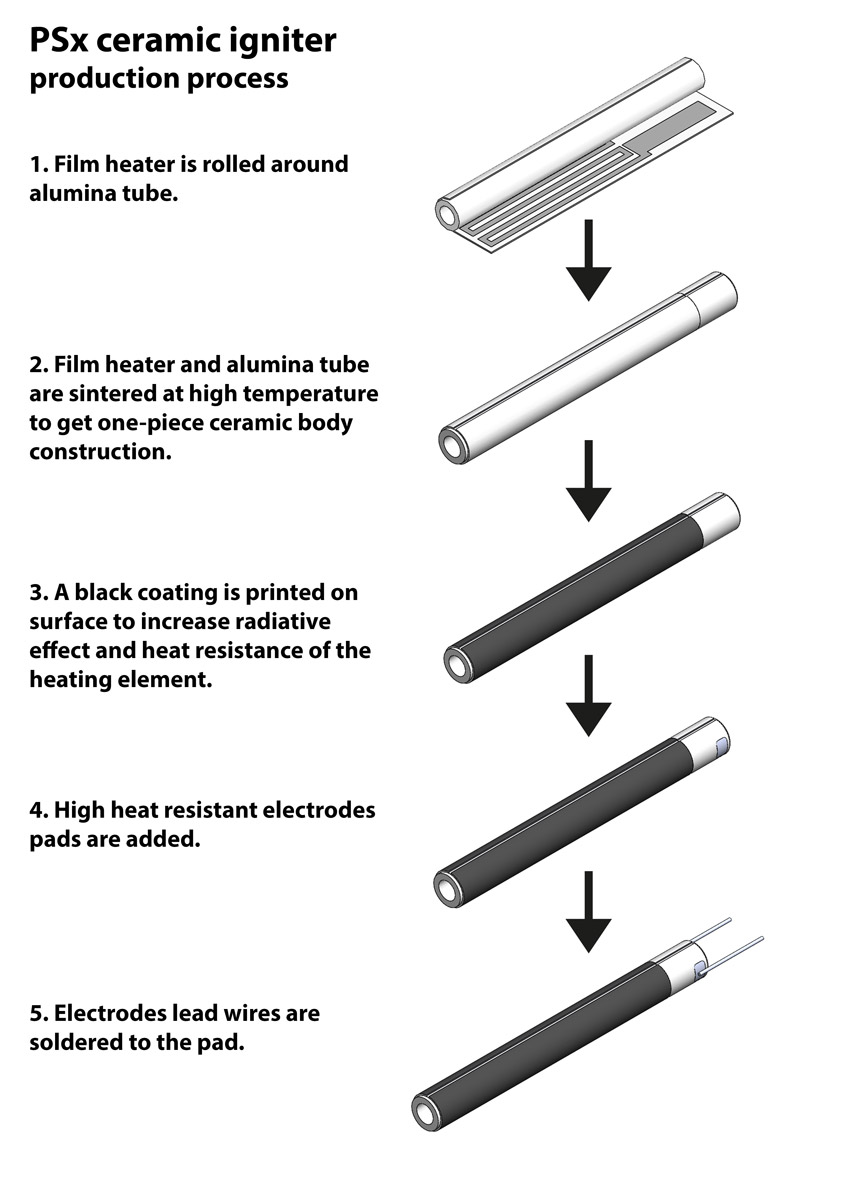

Here is the basic production process of a ceramic igniter:

- First, a thin film heaters (resistive heater) are printed on a thin substrate.

- Then, the film is automatically rolled around an alumina ceramic tube.

- The film and alumina tube sub-assembly is then sintered into one piece.

- A last step consist in adding electrodes pads and electrode lead wires.

In addtition FKK PSx igniter (230V) are coated in black to increase radiative effect and heat resistance of the heating element, making them the most robust igniter of the market.

Physical principle

A heating element converts electrical energy into heat through the process of Joule heating (same principe that make incandescent light bulb glows). Electric current through the element encounters resistance, resulting in heating of the element.

Ceramic igniter are PTC ceramic elements: PTC ceramic materials are named for their positive thermal coefficient of resistance (i.e., resistance increases upon heating). That mean that they have a highly nonlinear thermal response, so that above a composition-dependent threshold temperature their resistance increases rapidly. This behavior causes the material to act as its own thermostat, since current passes when it is cool, and does not when it is hot, so the temperature stabilize at a certain tempereture (950~1000°C).

Advantages of ceramic pellet stove igniter:

- High-Temperature (950~1000°C)

- Rapid heat increase (950~1000°C) in less than 60s

- High watt density, good thermal efficiency (save energy compare to metal cartridge heating element)

- Long Durability

- Do not over-heat/ Stable temperature

- Superior dielectric strength and electrical insulation

- Don't oxidized

- Small Size/High Output (compact compare to traditional heating element)

- Excellent Mechanical Properties